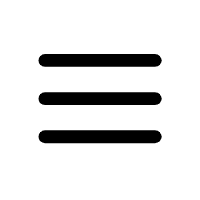

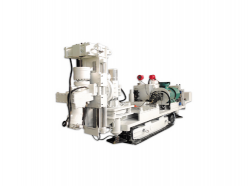

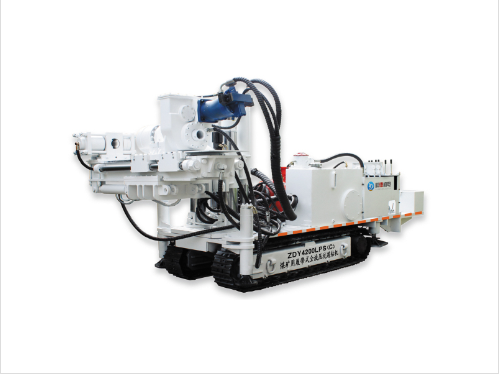

Crawler type fully hydraulic tunnel drilling rig for coal mines (side mounted)

Category:

Keywords:

Applicable Scope · Applicable Scope

This type of drilling rig is a crawler self-propelled, low-speed, high-torque type, and is used for various types of drilling in coal mines (regional pre-extraction drilling, working face drilling, geological drilling, etc.). It can realize the hole layout requirement of 360° in the full cross-section. The drilling rig has powerful drilling capabilities and can carry out drilling operations under complex geological conditions, thereby improving mining efficiency and safety performance.

Product Features · Product Features

1. The drilling rig has a compact structure and good flexibility, and can adapt to different geological environments;

2. The minimum drilling height of the drilling rig is low, enabling all-round drilling operations within 360°;

3. The drilling rig adopts a side-mounted structure design to facilitate drilling operations in ±90° directions;

4. The slide uses a design that combines flat guide rails and cylindrical guide rails to effectively extend the service life of the slide;

5. The drilling rig has large feed and pull-out forces, making it easy to handle special situations in the hole;

6. The drilling rig is equipped with a slide (slide rail) secondary feeding device, which can realize cross-belt operations;

7. The equipment adopts an integrated valve, which makes the operation centralized, simple and convenient. It can be far away from the orifice during operation, making it safer and more reliable;

8. The drilling rig has a variety of safety protection measures, including overpressure protection, electrical protection, hydraulic self-locking, etc., to ensure construction safety;

9. You can choose to replace different types of chuck slips and holder slips to adapt to different drilling diameter and depth requirements;